Pumps and filters in the textile industry

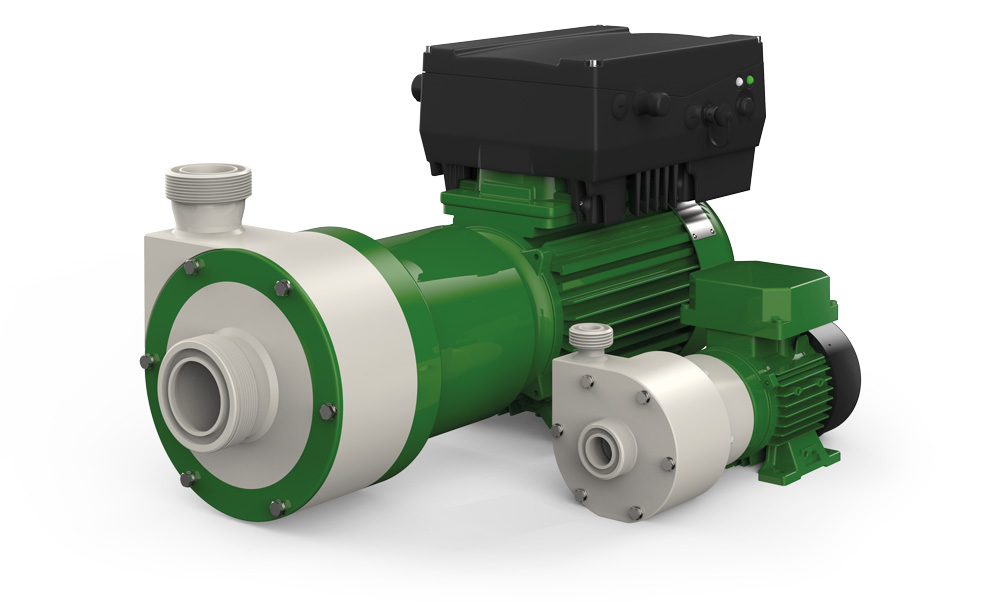

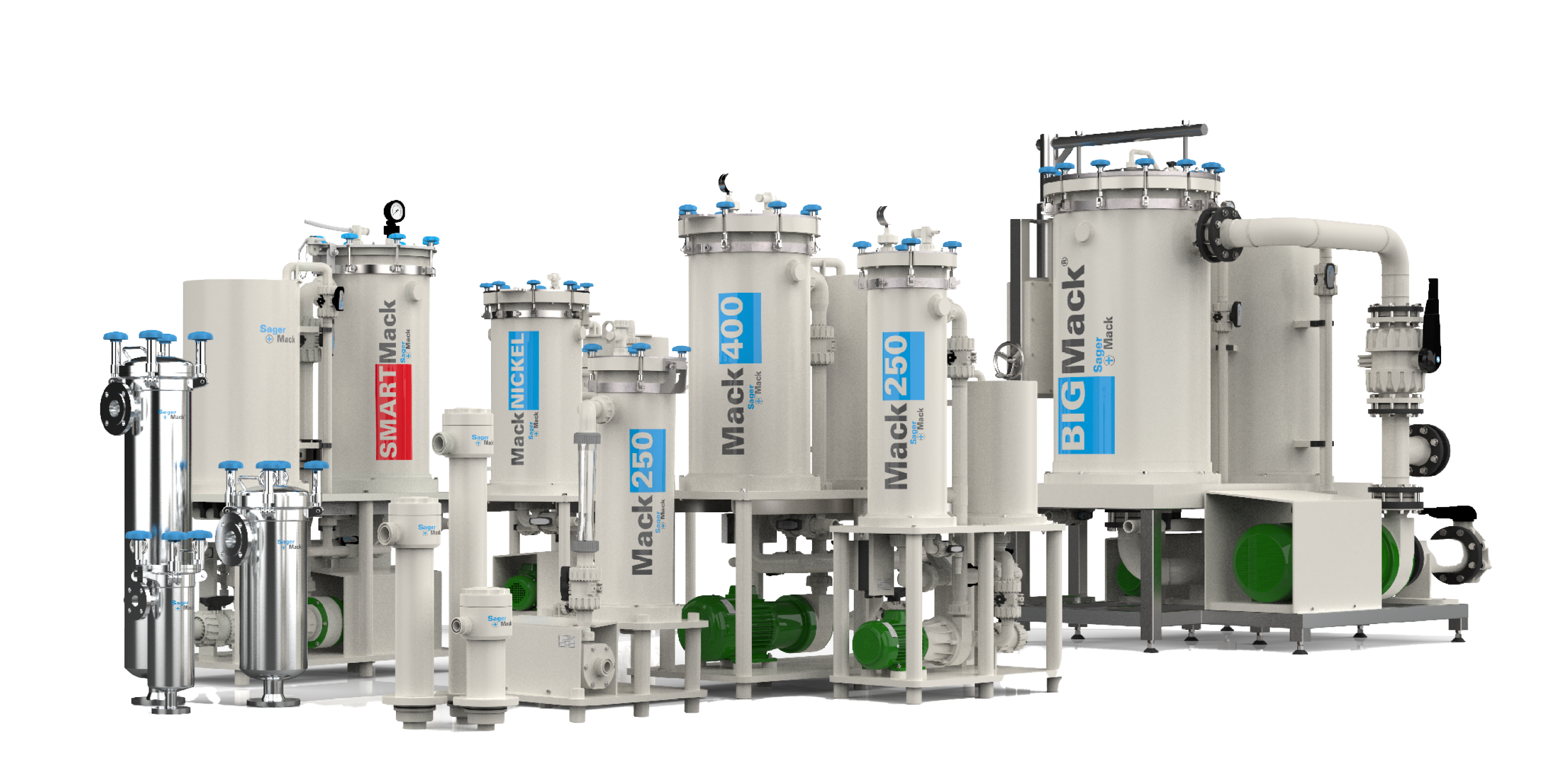

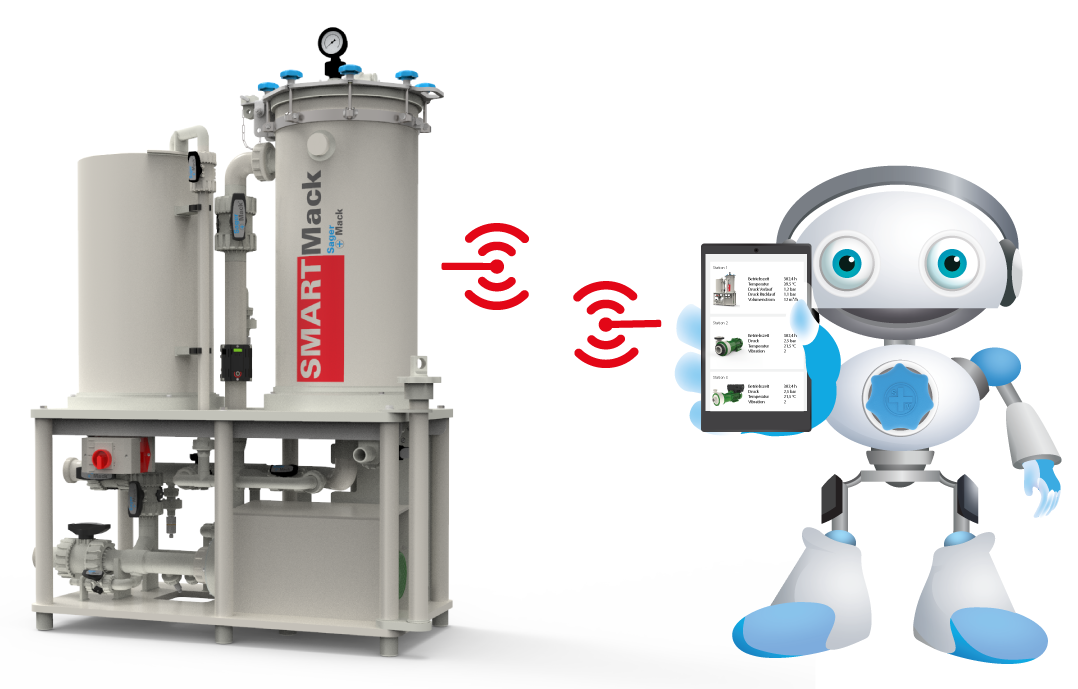

The production of textiles places high demands on efficiency and environmentally friendly processes. Since chemically aggressive and health-hazardous substances are often used in liquid form in washing, dyeing and cleaning, their safe handling for personnel and the environment is required. Sager + Mack supplies suitable equipment for the transfer of water, acids and alkalis, e.g. for use in waste water treatment. Filtration and transfer processes as well as the circulation of circulating media are only a part of the tasks that are reliably fulfilled in textile laundries as well as bleaching plants or dyeing machines. Sager + Mack is a supplier of robust, durable technology for both production companies and plant manufacturers in this market segment.