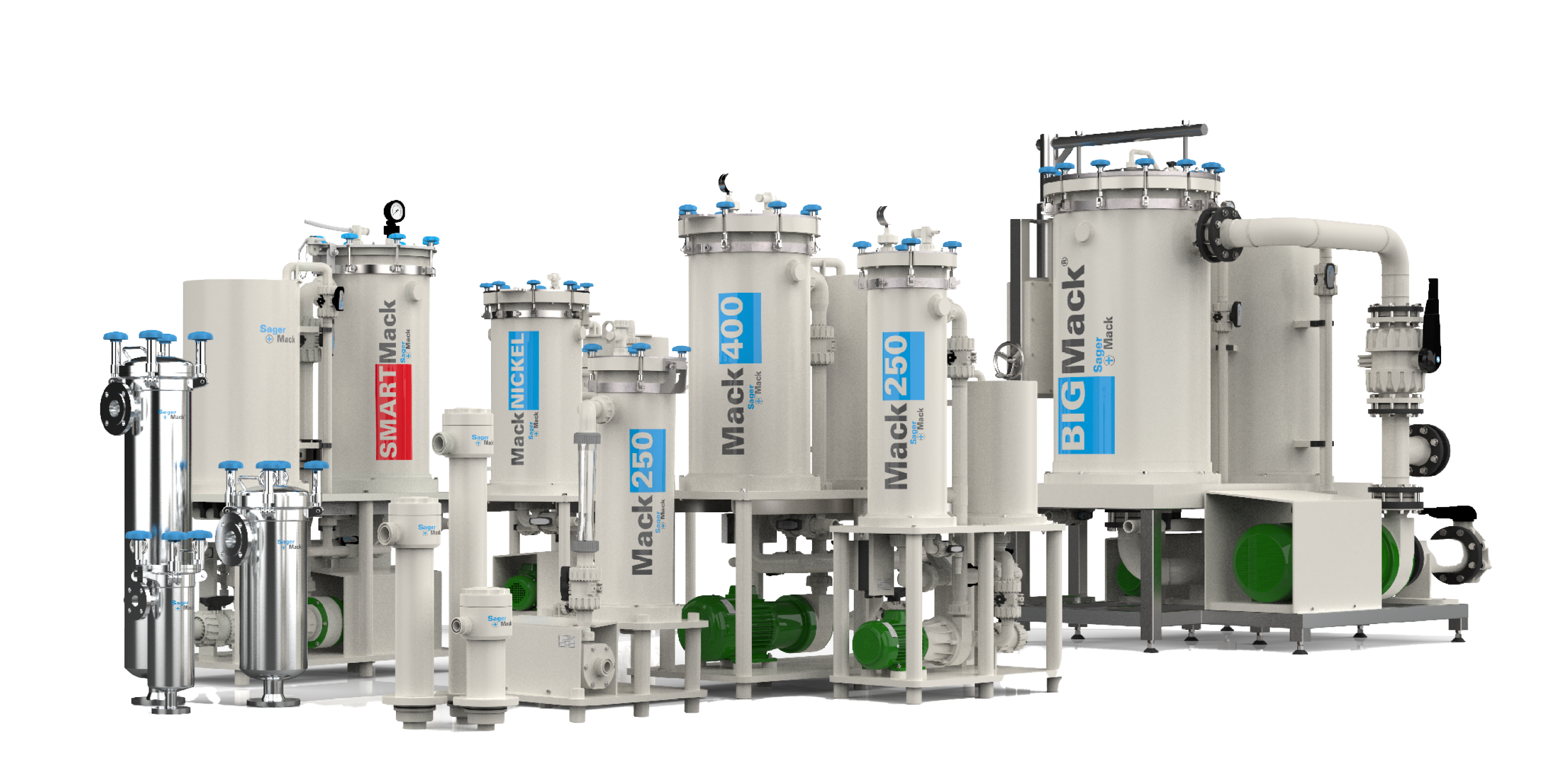

FILTER TECHNOLOGY -Sager + Mack offers you a large product portfolio of filters – in the metal industry, these can of course also be used for recycling operating fluids.

Bag filters for cooling lubricants make it possible to separate the unwanted solids from the circulating cooling lubricant. In doing so, the optimum cooling and lubricating effect is maintained. Other positive effects of this filtration are, for example, the prevention of clogging (e.g. of nozzles), reduced wear due to abrasion (e.g. in the lines or on the tool),

as well as a potential improvement of the workpiece surface.

The use of adsobrer filters for circulating cleaning fluids, for degreasing plastic or metal parts, extends the life of the degreasing solution. The service life of the medium can thus be tripled until a fluid change is required. Not only free oil but also emulsified oil is removed.

Quick-lock and twist-lock filters allow quick and easy filter changes with minimal downtime. The lever on the quick-release cap allows the filter cover to be opened with a single movement, so changing the filter takes only a few seconds. The twist or screw cap provides a similarly simple, cost-effective alternative.

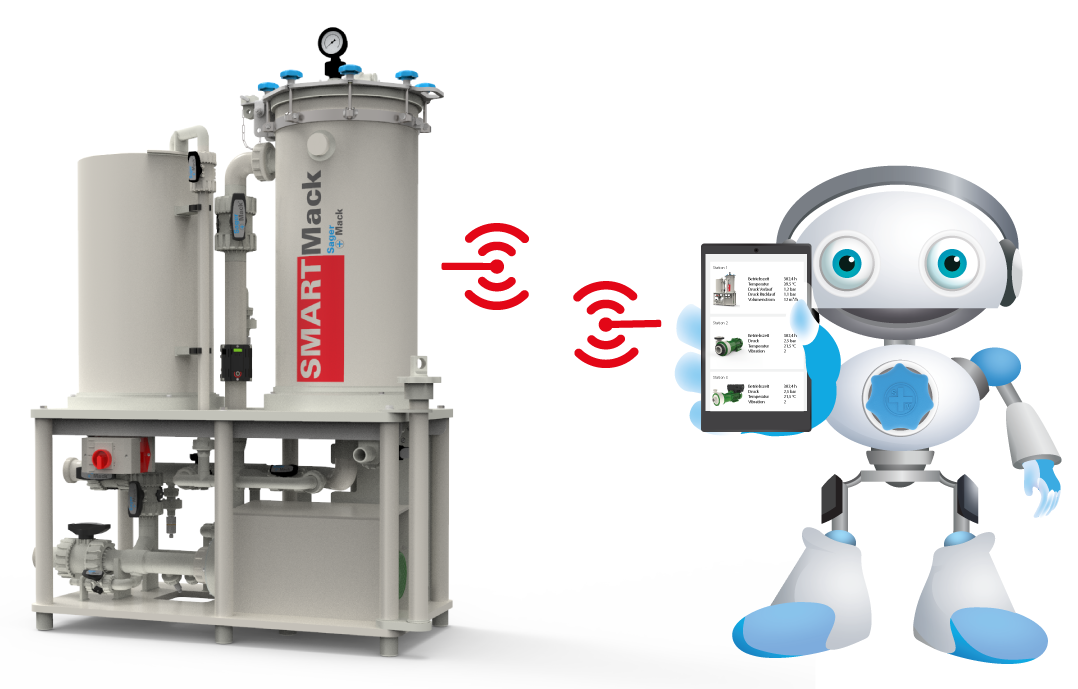

FILTER STATIONS FOR THE METAL INDUSTRY

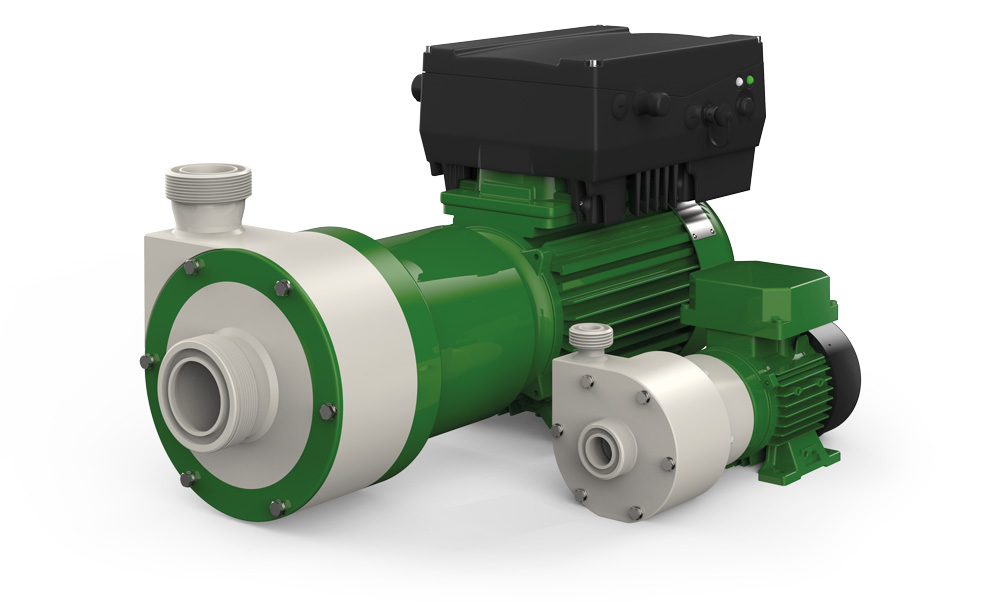

Simple and customized solutions allow the adaptation of Sager + Mack filter units into existing production facilities in the metalworking industry as well as the dimensioning and new installation for newly built production plants. Submersible filter units, a combination of submersible pump and filter tank, can be easily retrofitted, for example, to supplement existing machine tools and multiply the service life of the cooling lubricants. Likewise, complete filter stations offer the possibility of cleaning baths permanently in circulation, thus keeping the quality of cleaning stable and reducing the use of expensive and environmentally harmful cleaning chemicals to a minimum.