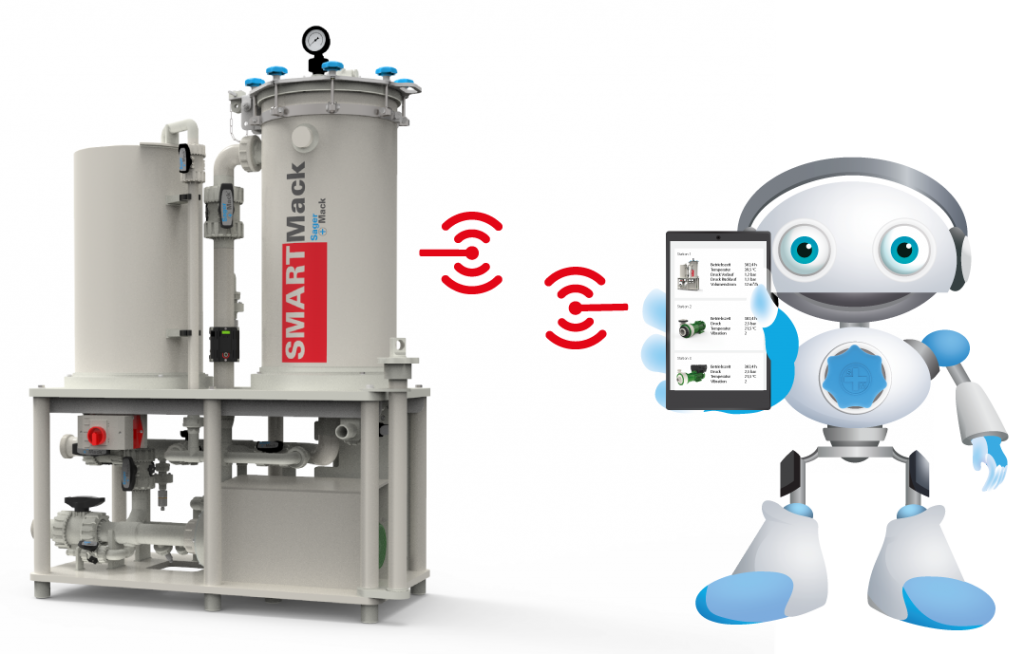

SMART MACK

KEEP INFORMED…

- All relevant data of your filter station at one view

- More effective maintenance to reduce production stops

- Remote diagnosis via P-Cloud directly with the producer

- Enables plannable maintenance intervals

- More effective usage of filtermedia / consumables

- Possibility to combine with an Online-Shop for Filtermedia

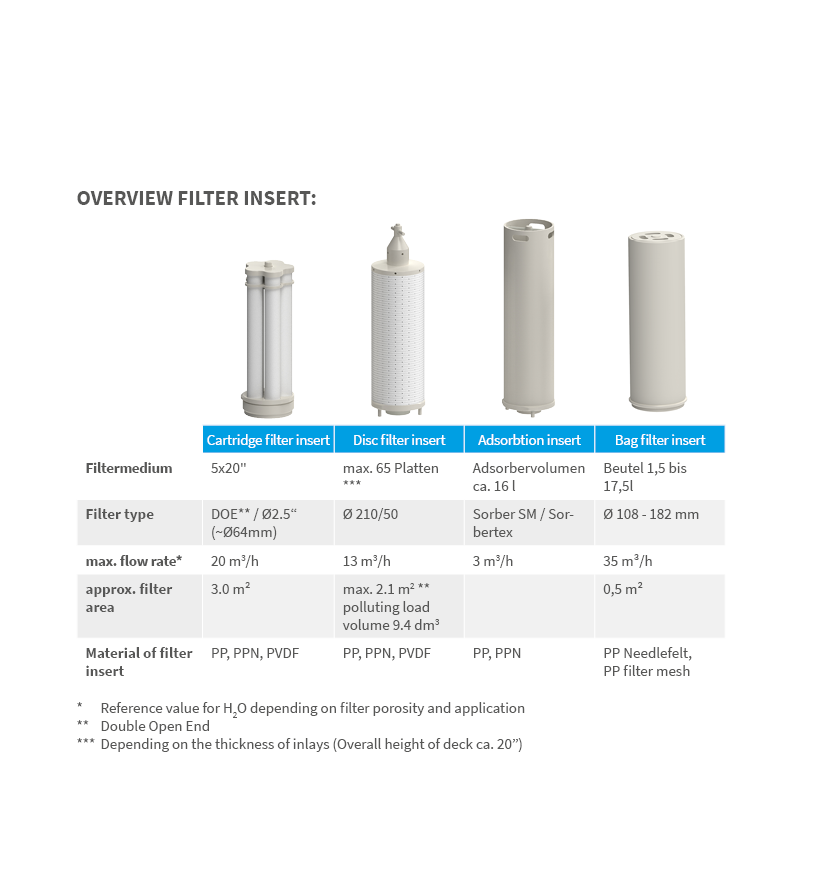

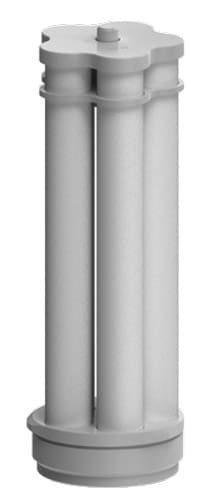

- The filter housing made from PP material is multifunctional: It is matching for different filter-inserts like cartridge-, disc-, or adsorbtionfilter

- Easy handling: the PP filter housing allows a fast and easy change of the filter medium without any tools

- Horizontal filter inlet on top – vertical filter outlet on the bottom

- Housing drain for reduced cleaning effort

- Non-metallic solution contact for plastic version; this means high chemical resistance

- The housing cover is equipped with a stainless steel reinforcing plate and with a surrounding splash guard for additional safety

- This housing is designed for pressures up to max. 3 bar

- Categorization acc. to Directive 2014/68/EU

- Application area: GMF, PCB, waste water and many others

- Including a horizontal magnetic driven pump